Water Lab Combines Sustainability, Human-Centered Design to Win 2025 Design Excellence Award

Staircase connecting the roof terrace and courtyard. Image: EVABLOEM

In the heart of the Netherlands, the Aquon Water Research & Analysis Laboratory in Houten is redefining what a sustainable laboratory can be. Designed by Vakwerk Architecten, this 7,340-sm facility supports Aquon's mission of safeguarding regional water quality through robust scientific analysis—while achieving new benchmarks in environmental performance, efficiency, and occupant wellbeing.

The project team included Vakwerk Architecten (architecture), Labadvies (lab planning), Arcadis Nederland (MEP), Pieters Bouwtechniek (structural engineering), and Wam & Van Duren (main contractor).

This project was honored with the Excellence in Sustainable Design prize in the 2025 Design Excellence Awards. Representatives accepted the award at the Lab Design Conference in Denver, CO, in May 2025 and shared insight into the project with the conference audience. Speaking with Lab Design News, project architect Begoña Garcia Giner and lab planner Christopher Perry shared insights into the building's forward-looking strategies and the collaborative process behind its success.

A hybrid approach to structure and sustainability

Laboratory with large windows overlooking the surrounding landscape. Image: EVABLOEM

The building takes a bold yet balanced approach to materials. Laboratories are constructed in concrete and steel to accommodate technical demands, while the office, meeting, and communal spaces are built from mass timber. This hybrid system reflects a clear design logic—durability and safety for the labs and warmth and wellbeing for the people.

"In an ideal world, we would have made the whole thing out of mass timber," says Perry. "But there were concerns about the nature of the research and whether timber was an ideal material for the lab. Therefore, we compromised by having a hybrid combination of the materials."

Garcia adds that approximately 40 percent of the building is biobased, a significant figure for a lab project of this scale. The team wanted the materials to reflect both sustainability goals and the identity of Aquon, she notes. "We did our best in the areas that we could to make sure the use of wood could compensate for the use of concrete and steel, and also add the warmth and the qualities to make it a more sustainable and healthy environment for the employees. That's where the other side of sustainability and healthy environments comes into play."

Innovative energy and ventilation systems

Laboratory with glass partition for a complete overview of the entire area. Image: EVABLOEM

The Aquon facility is built with adaptability and circularity at its core. Modular lab layouts based on an oversized 8.1-meter grid provide flexibility for future reconfiguration, whether to accommodate new equipment, changes in biosafety levels (from ML1 to ML2), or the integration of automation.

"We settled for a rather oversized module because it just gave us the flexibility to accommodate more activities and anticipate what might happen in the future—where it's not only people but robots and machines," explains Perry. The generous module, he notes, helped the team anticipate future shifts—more robotics, more services, perhaps even new research processes that can't be predicted yet.

Concrete and steel elements were detailed for potential disassembly and reuse, enhancing the building's long-term sustainability profile.

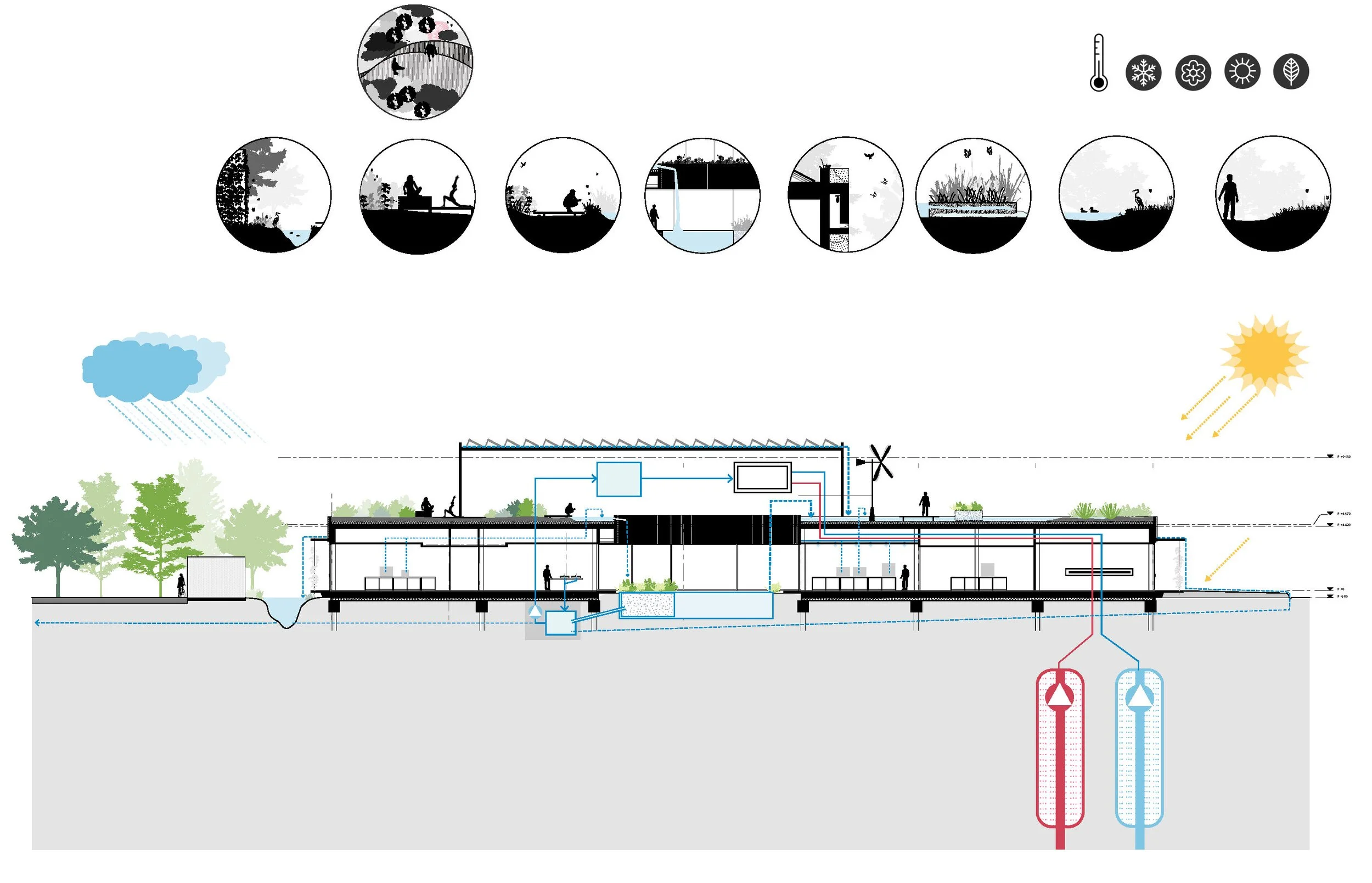

Energy efficiency played a central role in the project's performance goals. To further reduce energy consumption, the design team implemented heat recovery systems on both general ventilation and high-volume fume hood exhausts, which are typically significant sources of energy loss in labs. The building uses an Aquifer Thermal Energy Storage (ATES) system—a solution particularly suited to the Netherlands' climate and water table.

Water and environmental systems. Image: Vakwerk Architecten

"It's quite a Dutch system because the water table is so high in the Netherlands," says Perry. "It's relatively easy in summer to put aside warm water for heating during the winter, and then in winter to put aside cold water to help balance out your cooling load in summer." This approach enables the Aquon facility to utilize the temperature variations between seasons, leveraging the groundwater system as a buffer. The large thermal store located under the building helps to balance the system throughout the year.

Expressing identity through materials and landscape

Entrance area looking into the laboratories. Image: EVABLOEM

A standout design feature is the use of reclaimed sheet piling planks on the building façade. This textured, weathered wood—commonly used in Dutch waterway infrastructure—reflects Aquon's deep connection to water research while reinforcing the project's circular economy principles.

"When we suggested this idea to the client, they were really happy about it because it really spoke to them as part of their identity," Garcia says. "They do a lot of fieldwork, and they're out in the canals picking up samples, so it is part of the nature of the work."

The rooftop landscape, inspired by regional wetlands, provides more than aesthetic value. It enhances biodiversity, manages stormwater, and offers a restorative space for staff. Recessed meeting rooms and a canteen open directly onto the rooftop garden, encouraging use and fostering connections between departments.

Since the Aquon site is located in an industrial area, Garcia says, the designers wanted to create a contrast by offering an immersive landscape experience that elevates the daily work environment. "There was a conscious decision to have all workspaces downstairs on the ground floor, close to where the labs are, and bring the canteen and meeting rooms upstairs," she says. The layout encourages people to step away from their work, enjoy the view and fresh air, and connect with colleagues—fostering both casual networking and collaborative discussions.

Human-centered design for scientific precision

Main entrance as seen from the parking area. Image: EVABLOEM

Aquon processes over a million water samples annually, with plans to expand this capacity. Efficiency was non-negotiable, but so was wellbeing. "We established a very simple scheme," says Garcia, explaining that a ring of processes is situated around the building with the people at the heart. The approach is designed to foster collaboration and cross-pollination among different departments.

"Transparency and clarity were important as well," Garcia adds. "In that, you can walk into the building, and within a quick walk around, you can orient yourself."

Natural light reaches nearly every corner of the building, thanks to the shallow plan, two large courtyards, and triple-glazed windows with shading elements. These choices reduce energy demand while fostering a positive atmosphere for both lab staff and administrative teams.

Garcia and Perry credit Aquon's clear vision and the strong client/design team relationship for the project's success. "It was a very smooth design process because the client was always very clear as to what they wanted, and they were realistic about their budget," says Perry. "It was a modest budget, but it was kind of a realistic budget."

As a result, the design process went well, and the outcome exceeded expectations.

"I think they're truly happy with the working environment," says Garcia. "I think it's a great upgrade from what they had, and I think they're really happy with it. And it feels like 'Mission Accomplished.'"